Post-VF Commodore Holdens will maintain Downunder flavour

/The end of car-making isn’t the end for Holden – Australia’s GM operation has a key ongoing role adding a finishing polish to future product from around the world.

‘MADE-in-Australia’ won’t stick after VF Commodore production ceases at the end of 2017, but Holden cars beyond that point will still benefit from across-the-Tasman design and dynamic input, which is good news for Kiwis.

This assurance comes from Holden New Zealand boss Kristian Aquilina as well as the bloke he reports to, Holden Australia managing director and chairman Mark Bernhard (right).

“That was part of the reason for maintaining our engineering and design capability,” says Aquilina.

“Between Australia and New Zealand we have enough substance and volume to maintain influence, to ensure that we can do things a little differently.”

Comment suggesting Holden hands will touch most, if not all, of the 24 new cars set to serve under this badge post the VF Commodore came as Motoring Network toured the two assets exempted from next year’s shutdown.

Access to the design studio within Holden’s Fisherman’s Bend head office in Melbourne and the Lang Lang proving ground in rural Victoria is rare. Both are normally firmly off-limits to outsiders.

However, Holden wants to prove it is still in the game – even though it doesn’t have as many helping hands as it once did.

The ground-up vehicle development role that it once held is already history and the formidable array of engineering skills has diluted with the dismissal of 700 engineers who produced vehicles for Australian manufacture.

However, about 300 engineers and technicians spread between Lang Lang and the Port Melbourne engineering centre are engaged to provide services for global sister brands. They’ll also undertake local tuning for Australian and New Zealand conditions.

Bernhard is not discounting that some overseas’-sourced low-volume product in Holden’s future might not be finessed in Australia, but says in those instances Holden will keep control through insistence those vehicles are factory-calibrated at source to meet its expectations.

“Basically it’s down to a volume play. If we were going to bring in something that was in a count of say 500 cars then we are not going to run laps around Lang Lang … if we are going to sell them in the thousands then we will.

“We have a lot of people working on making sure our products have the right ride and handling for the conditions that Australians and New Zealanders experience.”

Those volume models range from everything from more small cars to a greater variety of sports utilities, at least one heavy-hitter sports machine and, of course, the next Commodore.

All will benefit from the local expertise retained on the Fisherman’s Bend payroll. (Assuming that famous location remains Holden’s HQ; the long-mothballed car plant alongside the offices on the 37-hectare site is being eyeballed for urban renewal).

Aquilina says the ongoing Australian input is a good news story for Kiwis and reminds that Holdens will still, at heart and in attitude, be Holdens when the car-making plant in Adelaide closes in October, 2017.

“It’s important. One of the key points of difference, one that we and our customers value, is our Australasian origin.

“Our past that has been largely around manufacturing but we are continuing an engineering and design capability.”

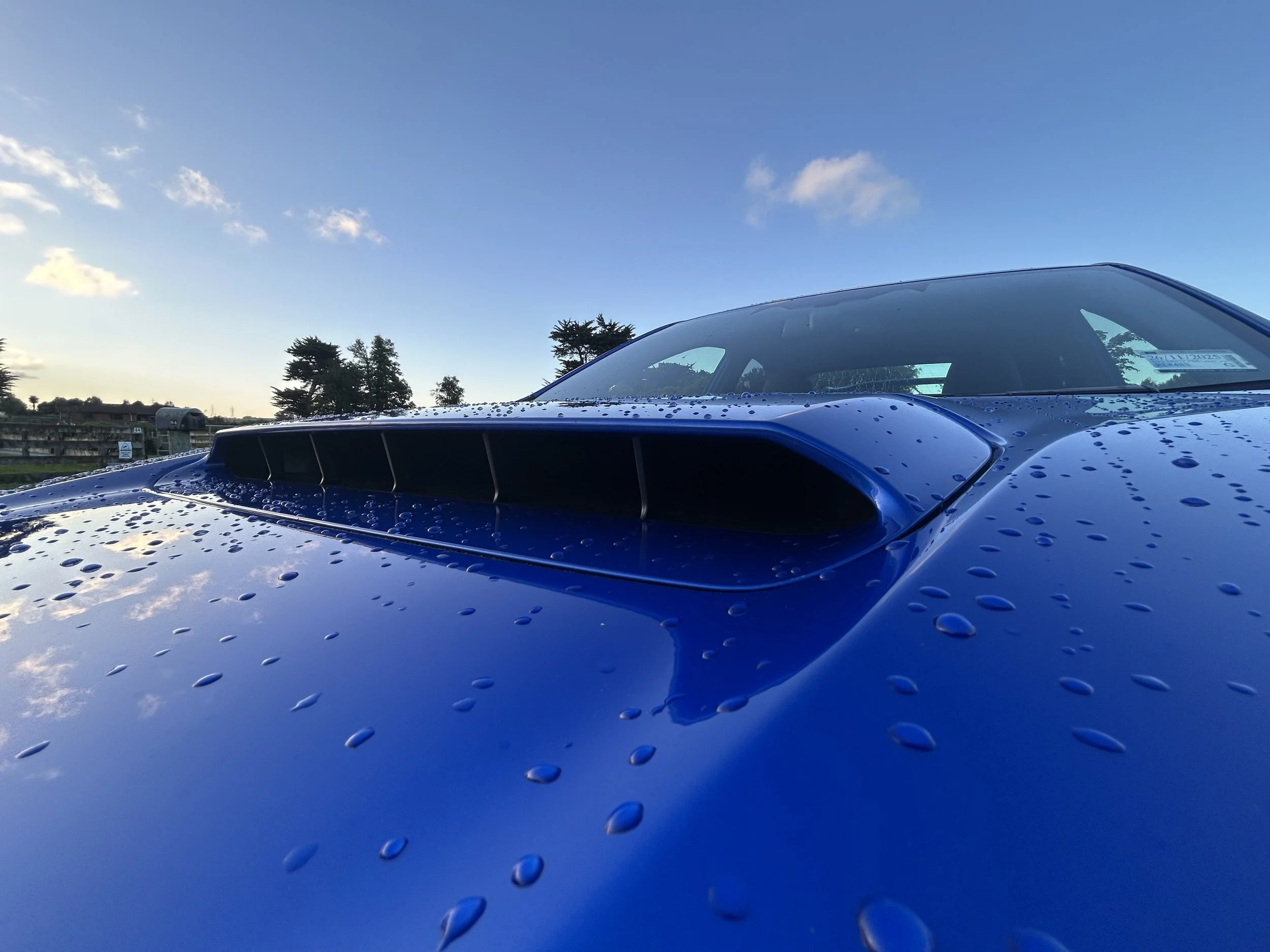

He says the test roads at Lang Lang, left, should not be considered as reflective simply of Australian conditions; they’ve a touch of Kiwi, too.

“We may not be building cars for this part of the world (after next year) but the stuff that really matters to consumers – how we design and engineer cars for this part of the world – that’s being retained.”

The car we came to Melbourne to drive this week is a good example of Holden’s new way. The newest generation of the Spark small hatchback, a 1.4-litre five-door, is designed in South Korea and will be sold globally; as well as being a Holden it’s also a Chevrolet, a Vauxhall and an Opel.

Recalibration of the steering and suspension, plus optimisation of the stability control and anti-skid brakes for our market condition was undertaken at Lang Lang. While the exterior and interior were crafted by Koreans, their workplace – a studio in Seoul that has responsibility for many GM compact cars now – is one of several under the auspices of Mike Simcoe, the Aussie who has since 2014 been vice president of design for GM International.

The GM Design Australia studio, run by Holden design director Richard Ferlazzo, below, is also important. The man behind one of GM’s most celebrated concepts, EFIJY – 2007’s hotrod tribute to an original Holden hero, the 1950s FJ – assured his 140-strong team is still fully engaged in design work for the full gambit of GM brands.

It’s also making fully operational concepts, the most recent being the Opel GT, a slinky coupe at the current Geneva motor show. GM Design Australia was also responsible for the Buick Avenir study for last year's Detroit show, where it was judged best concept.

Buick had a spin-off coupe, Avista, at Detroit in January and though Ferlazzo’s crew did not involve with the design or build, the lineage is clear. There is conjecture Avista might eventually be sold wearing Holden badges.

A presentation by Ferlazzo made clear his operation in deeply immersed in work for Chevrolet, GMC, Cadillac, Buick, Opel and Vauxhall. Plus, of course, his own employer.

Back at the 877-hectare Lang Lang site change is in the air. A facility opened in 1957 is getting a 60th-birthday makeover in the form of multi-million dollar overhaul that will include a new emissions testing lab and bitumen resealing works for the massive circular 4.7km high-speed banked loop.

Had GM stuck to its original thinking, Lang Lang would have closed.

Back in 2013, when it was embroiled in a Chapter 11 bankruptcy as result of the global financial crisis, Detroit decided the proving ground and associated engineering operation would go, along with Holden's factories in South Australia and Victoria. A year later, however, GM International president Stefan Jacoby announced a reprieve for the proving ground.

Staffing has been reduced – among those let go were test drivers engaged in durability testing, a function mostly associated with local vehicle development – and mechanics who maintained those cars.

But maintained is powertrain calibration, a Holden speciality. GM last year announced this kind of testing will continue at the proving ground, mainly for Opel and Chevrolet.

As well, chassis engineers who did the global suspension tuning for the current Chevrolet/Holden Trax are continuing to refine new models, including the updated Trax out in January, 2107.

They’ve also been engaged on the facelifted Colorado ute and Colorado 7 releasing later this year.

Meantime, Bernhard says Holden’s transition from being a manufacturer to a sales and distribution is well under way and has not without challenges.

“With that evolution the brand becomes more important. We’ve been able to live on the reputation as being Australia’s own car company for a long time now and we certainly have a lot of heritage.”

Yet Holden does not intend to rest on its history. Sales are down in the home country and improving customer satisfaction has become a priority. The brand has hired an expert from the country’s top telco and has started lifetime capped price servicing and made warranties more enticing. Some of these inititiatves are being considered by Holden New Zealand.

Above all, it is still battling perception that the end of manufacturing is the end of Holden. That’s why the brand is speaking so frequently and so loudly about its future product push. He perceives this is less of a problem in New Zealand than in Australia; for Kiwis Holden has been an import brand since the Trentham assembly plant closed in 1990.

“But that’s why we talk about the future stuff; we need people to understand that we are not closing down. We are dealing with that as best we can, by talking about future product.”