Commodore’s ongoing delivery count under wraps

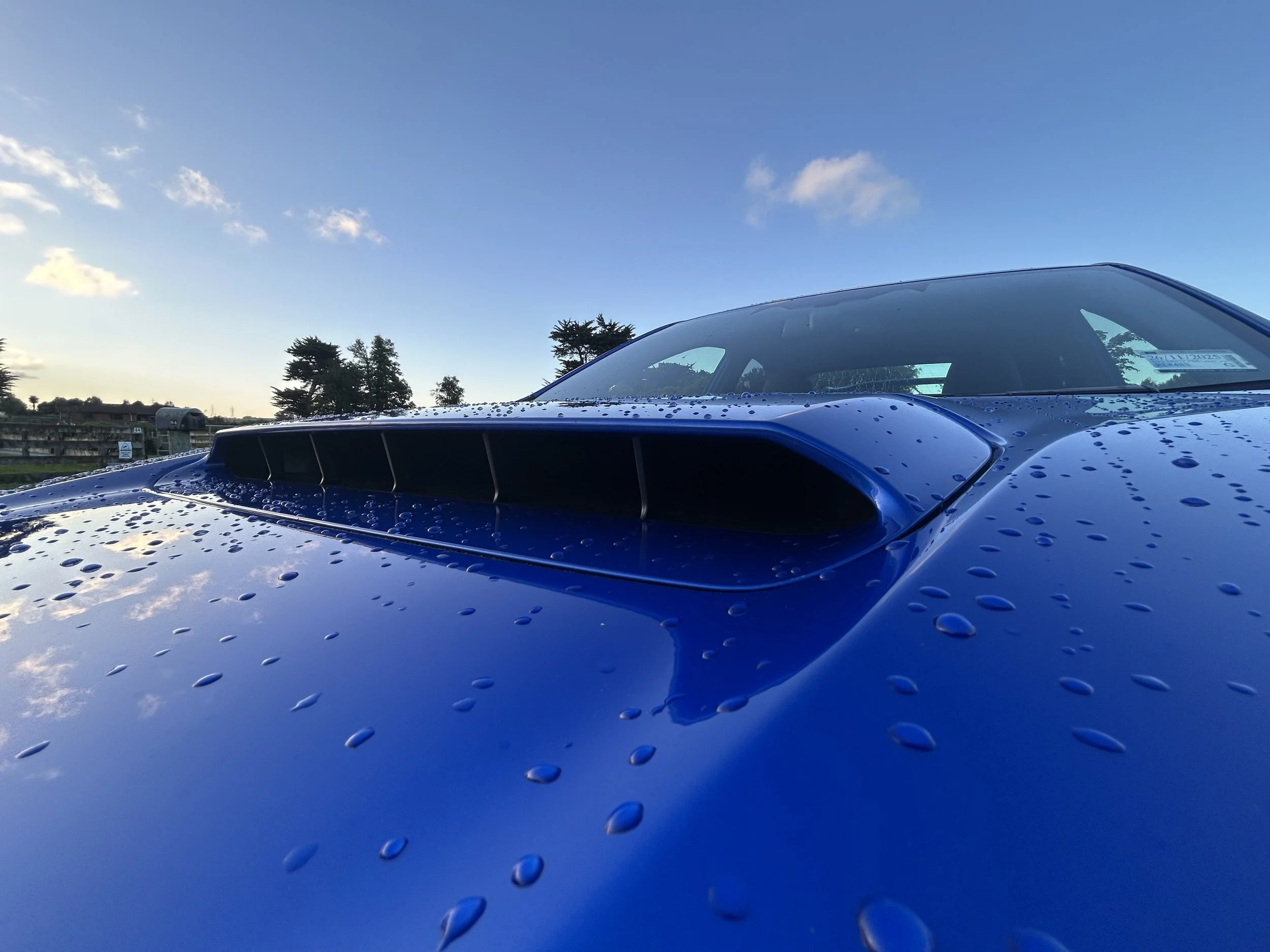

/Commodore as we know it will go out production on October 20. How many more of the Australian-made cars are coming here is not being divulged.

THIRTY thousand Commodores are set to built before Holden’s Adelaide plant closes up – but how many of these are New Zealand-bound isn’t being shared.

While the parent is happy to disclose the remaining total production count from the Port Elizabeth plant up to its closure on October 20, the New Zealand affiliate is being coy about how many cars from that run it will account for.

Suggestion from the Auckland head office that this is stuff just too sensitive to share might surprise, given that data that gives a good idea of its ambition is free to access.

The answer probably lays with annual registrations counts compiled by NZ Transport Agency.

This suggests that, with Holden New Zealand having annually sold over the past four years between 2453 and 3001 units annually, it moves between 225 and 250 examples a month.

Might there be a rush to secure the last of the Australian-made product, and thus a Commodore with rear-drive, a sedan format and a V8 engine as an option to the mainstream V6 – all options that the new, front-drive and hatchback formatted NG from Opel does not provide?

Special edition performance variants are also about to be announced to further elevate VF II's already solid social status, yet temarkably, Holden New Zealand has in the past suggested it does not anticipate any particular ‘last-chance’ buy-in stampede.

With that in mind, it seems solid to presume it could well import 1800 to 2000 VF IIs, predominantly sedans and wagons as the ute has always been fringe, over the next eight months.

But it’s just a guess. Spokesman Ed Finn was apologetic but resolute about discussing this.

“You're correct, the 30K Commodore … is the total number to be built between now and closure,” he told MotoringNetwork.

“But unfortunately I'm not in a position to divulge the number of these bound for New Zealand.”

Asked if he imagined there was potential that Commodore stock might exhaust in the interim period between the end of VF II build and the arrival, from Germany, of the new NG line, he said: “We are … confident that our sales planners have made the correct forecasts to ensure there is a seamless transition from the Australian-manufactured Commodore to the new European-sourced Commodore in 2018.”

Despite an apparent lift in interest in the performance SS variants, particularly the HSV-humbling SS-V Redline sedan, last year’s total local market Commodore sales count was the lowest since 2013, with 2453 finding homes.

The highest count in recent years occurred in 2014, when 3001 vehicles were registered. That tally apparently included an extra-big order of cars by the NZ police, the model’s primary customer.

Ongoing police interest in Commodore means they will be the NG line’s first customers. Patrol car variants are set to go into service around November, Holden NZ has suggested.

For regular customers, however, the NG has consistently been referred to as being a 2018 model – the patrol car delivery schedule appears to be about two months ahead of when the car reaches local showrooms.

It has long been thought that Holden will end its car-making programme across the Tasman around October, however the actual closure date was a tightly-guarded secret until its announcement several days ago.

Curiously, that announcement has only been made in Australia; Holden New Zealand – now the brand’s last export customer for Commodore - has not yet seen fit to pass on the news locally.

Holden has already begun its rebirth as a vehicle importer; the Port Elizabeth plant stopped making the Cruze on October 6 last year – on the same day that Ford closed its Falcon production line to terminate its car-making phase in Australia – and in November it also ceased making the Commodore’s staple V6 engine.

The plant closure, though, is the big news story – Holden has been making cars in Australia for almost 70 years and Port Elizabeth has been the central production centre since 1963. Every Commodore and its variants have come from there.

One positive: Nearly 70 percent of all the Holden workers that have departed the brand since the closure was announced two years ago have found alternate work within 12 months. Holden suggests that’s a reflection of the workforce’s quality.

In released comment, Holden chairman and managing director Mark Bernhard said Holden’s manufacturing workforce had set new benchmarks for quality and performance in the past four years.

“They have continually pushed to improve the quality of their work for the benefit of our customers – this commitment, continuous improvement attitude and passion have been exhibited in spades in challenging circumstances,” he said.

“It’s not surprising that their skills, work ethic and flexibility are highly sought after and they are leaving a legacy for Holden that deserves to be honoured by ensuring this company has a bright and successful future.”

Holden Australia will retain more than 300 designers and engineers, plus 10,000 employees at its headquarters in Melbourne - including the design studio at Fisherman’s Bend - at its Victorian proving grounds and through its dealer network of 230 dealerships.