Karoq set to go electric from next year

/NZ boss among guests given update on Elroq, updated Enyaq and two other impending electrics.

BATTERIES are set to include for a Skoda popular with Kiwis and though production release is still a year away, a name has already been chosen.

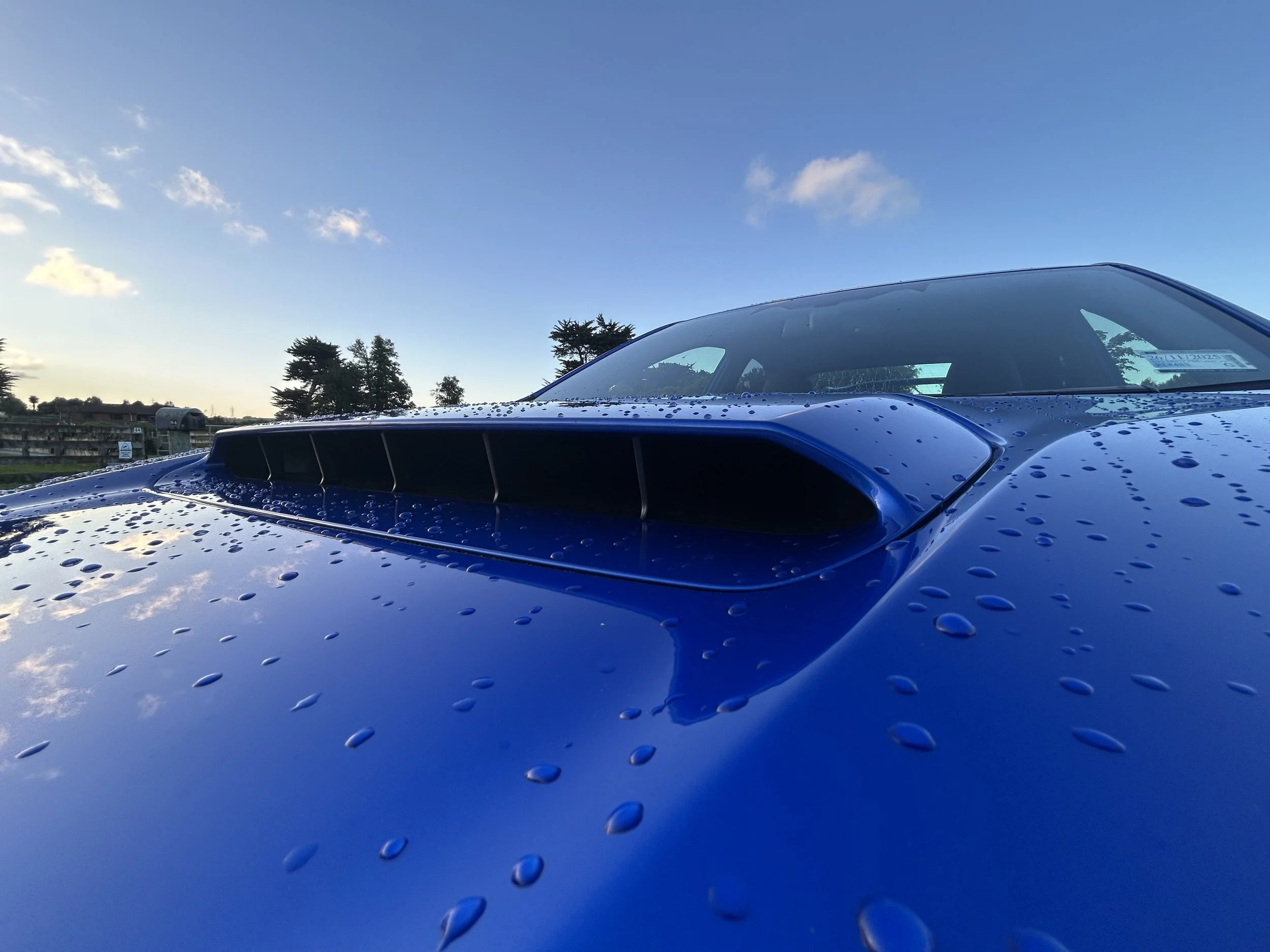

Elroq, the top image, is a giveaway. That’s a compound of ‘Electric’ and ‘Karoq’, the compact sports utility wagon (directly above) that presently accounts for a substantial slice of Skoda NZ business.

On the MEB platform common to all VW Group electrics, including the big brother Skoda Enyaq just coming into circulation here, Elroq is said to be 4.5 metres’ long – so, around 200mm longer than the Karoq.

It is the first of half a dozen new battery-dedicated products the Volkswagen Group’s Czech marque intends to release by 2026, all the subject of a just-ended symposium.

Two of those are big refreshes for the make’s first electric product, the Enyaq.

Also coming is a small budget hatch and a large, potentially seven-seater, sports utility wagon, both above.

Five of those propositions have been created as sculptures which Skoda has just shown off at its home base in Prague to global distributors – with Skoda New Zealand boss Rodney Gillard among the latter.

The ‘modern solid’ representations they saw officially lend first idea of the new designs.

However, Skoda has hinted that Elroq is much further advanced, while it’s also probable the updates for the next-size-up Enyaqs (above) – continuing in the wagon and coupe formats being pre-sold to Kiwis now for delivery in September – are being readied for road trials, given a 2025 release of the production cars is proposed.

The new designs take styling cues from a recent styling study, called the Vision 7S, especially in respect to front-end detail.

Not much is known about the Skoda Elroq’s motors or batteries just yet, however it’s likely to share parts with the Enyaq and deliver in singe and dual motor formats.

Overseas’ media are suggesting one role for Elroq will be to give additional life to the vRS performance brand that for now relegates in this market to fossil-fulled powerplants, though most recently in hybrid form.

The vRS – which simplifies to RS in Skoda NZ marketing – models have been popular with Kiwis and it has already been asked by the vRS Enyaq is not yet being included on the local roster.

Britain’s AutoExpress publication has report that Skoda chief executive Klaus Zellmer has told it that vRS is absolutely part of the make’s future.

“I think we have to continue along the vRS path as we move towards an electrified future.”

There’s conjecture Elroq vRS could have a 77kWh battery and two motors producing a combined 220kW and 460Nm of torque, with 0-100kmh in about six seconds, plus better agility and driver involvement than the Enyaq vRS. As a smaller car, it might be expected to also offer stronger range.

AutoExpress has suggested adaptation of proven systems should speed up development of the Elroq vRS.

Skoda Auto is core to VW Group’s electric strategy for more than just its electric products. The main plant in Mlada Boleslav produces battery systems for MEB cars and models with plug-in hybrid drive.

To date, Skoda has produced 500,000 battery systems for vehicles across the group. These are used in Skoda, VW, Audi and SEAT/Cupra product. Production capacity of MEB battery systems is set to increase to 1500 units per day at the facility, in addition to 800 plug-in hybrid units.

Skoda is investing heavily in the transformation of its facilities and development, digitalisation and further education of its workforce, with the company already upskilling more than 23,000 employees to prepare for the demands of e-mobility.

Since September 2019, high-voltage traction batteries for models with plug-in hybrid drive have been produced – a new unit arrives every 86 seconds. When it is being unloaded from the production line the battery weighs approximately 130 kilograms, with a team of 13 fully automated robots employed to handle particularly heavy components on the production line.

A year ago Skoda Auto launched the production of battery systems for all-electric vehicles based on MEB. The systems have a capacity of 55 to 82 kWh.

Along with the individual battery modules, each containing 16 cells or 24 cells, an MEB battery system also includes a case with an integrated cooling and a battery management system, as well as the necessary electrical connections. There are around 250 employees working at the current production line, in which Skoda Auto has invested more than $200 million.

Another MEB assembly line I is being commissioned this year, to increase total production volume to 2300 units per day, consisting of 1500 MEB units per day, and 800 units for PHEV battery systems.