Ace’s rally push goes electric

/Hayden Paddon is first on the road with an electric rally car.

images Geoff Ridder

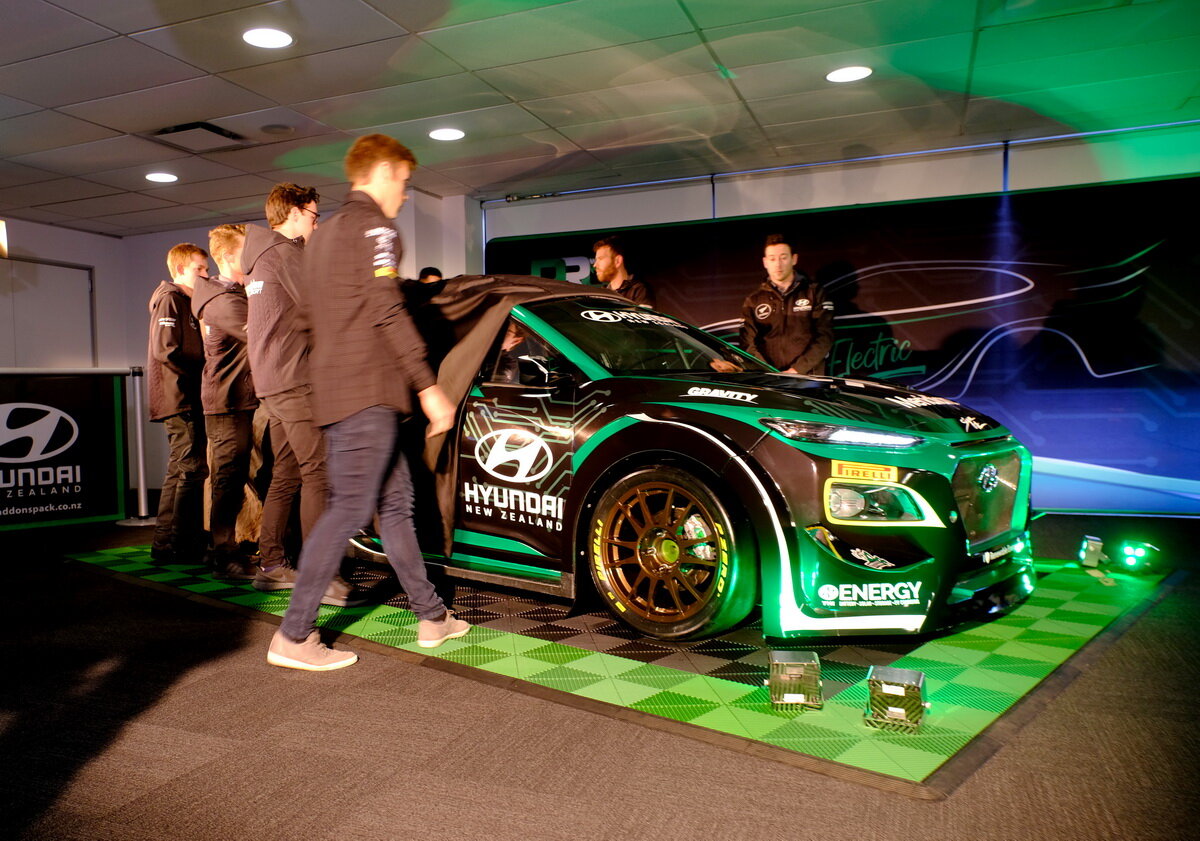

IN a variation on the theme of ``build it and they will come’’, rally ace Hayden Paddon faces a ``build it and they work out where you can take it’’ scenario with the fully electric Hyundai Kona rally car he unveiled today.

Paddon’s goal of competing in rallies with an electric car of comparable performance to modern day combustion engine gravel racers is not just a technology challenge. His pioneering programme means working with the sport’s local governing body to position the car in competition.

For the short term that means demonstration runs starting with a few quick blasts around the rallysprint course at the high-profile Battle of Jack’s Ridge event on Sunday November 14.

It will be a very public debut for a car that has only just completed two days of filming work.

By the end of November MotorSport New Zealand hopes to have published its first regulations for electric vehicles. Paddon’s hoping his car helps provide a framework for those rules.

``At the moment it’s going to be demonstrations,’’ said Paddon.

``Going forward we know we have to work with MotorSport New Zealand – one on the safety and two on the performance parameters to actually make it fit in.

``We have started that discussion but the key thing is nobody knows and we need the car running to see what it’s capable of. That gives us a benchmark to work from.

``I’d like to think within two years we can have it accepted within motorsport events including full-length rallies. In the short term we know people want it and it’s good for the sport.’’

There are few question marks over the performance potential of the car created by a small team of seven at Paddon Rallysport Group headquarters at Highlands Park.

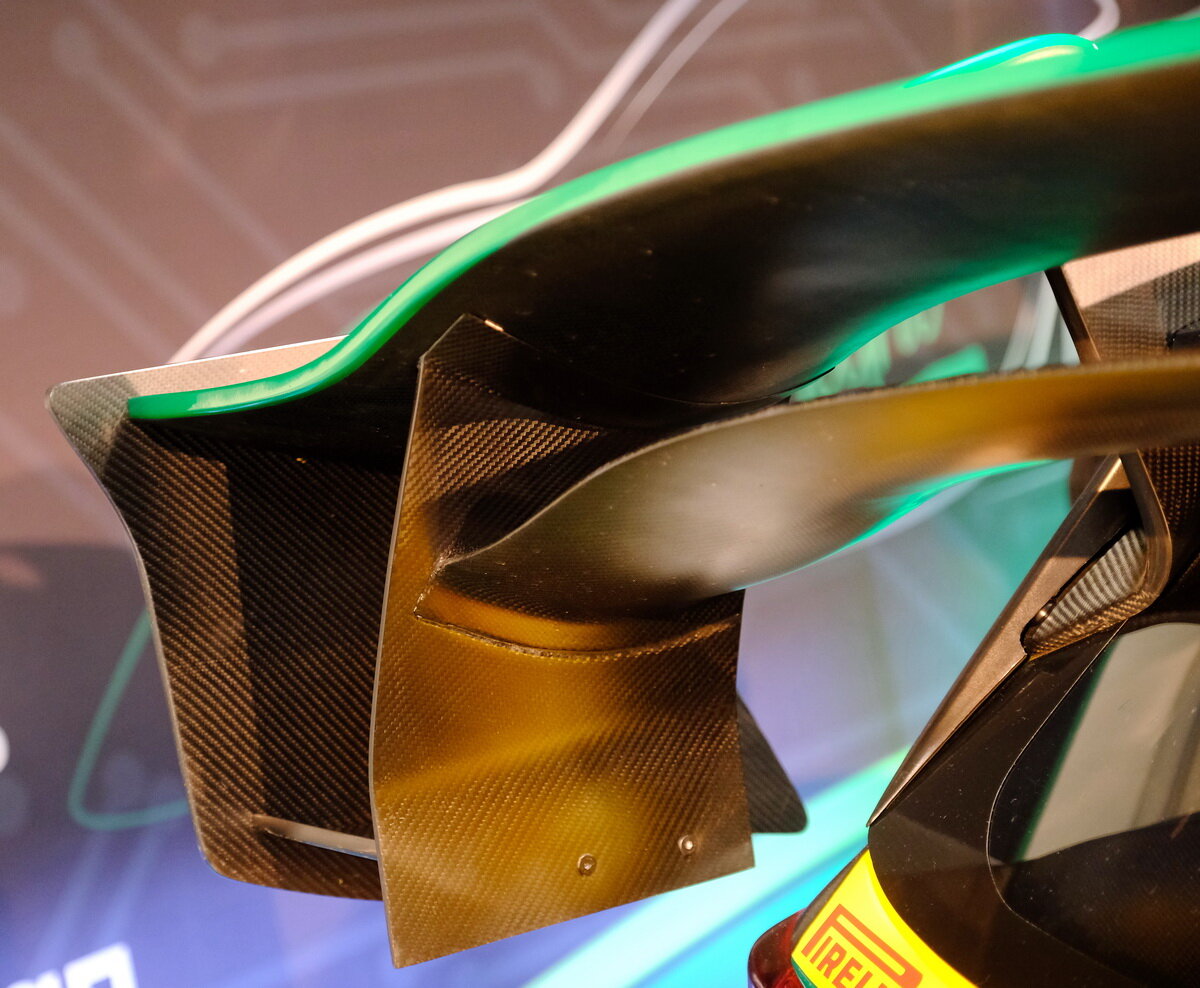

In its current guise the car has electric motors and two-speed transmissions front and rear. Each motor has peak power of 200kW and about 360Nm of torque. Paddon says the car is geared to reach 240km/h and can accelerate from 0-100km/h in a little over 3secs.

It’s possible to lift that performace adding another motor both front and rear to double the output to 800kW. Paddon says his initial goal is to tune the car so its comparable to the AP4-spec 4WD Turbo rally cars currently competing in New Zealand.

The EV is a little heavier at 1400kg but the weight is positioned low in the chassis of the Kona.

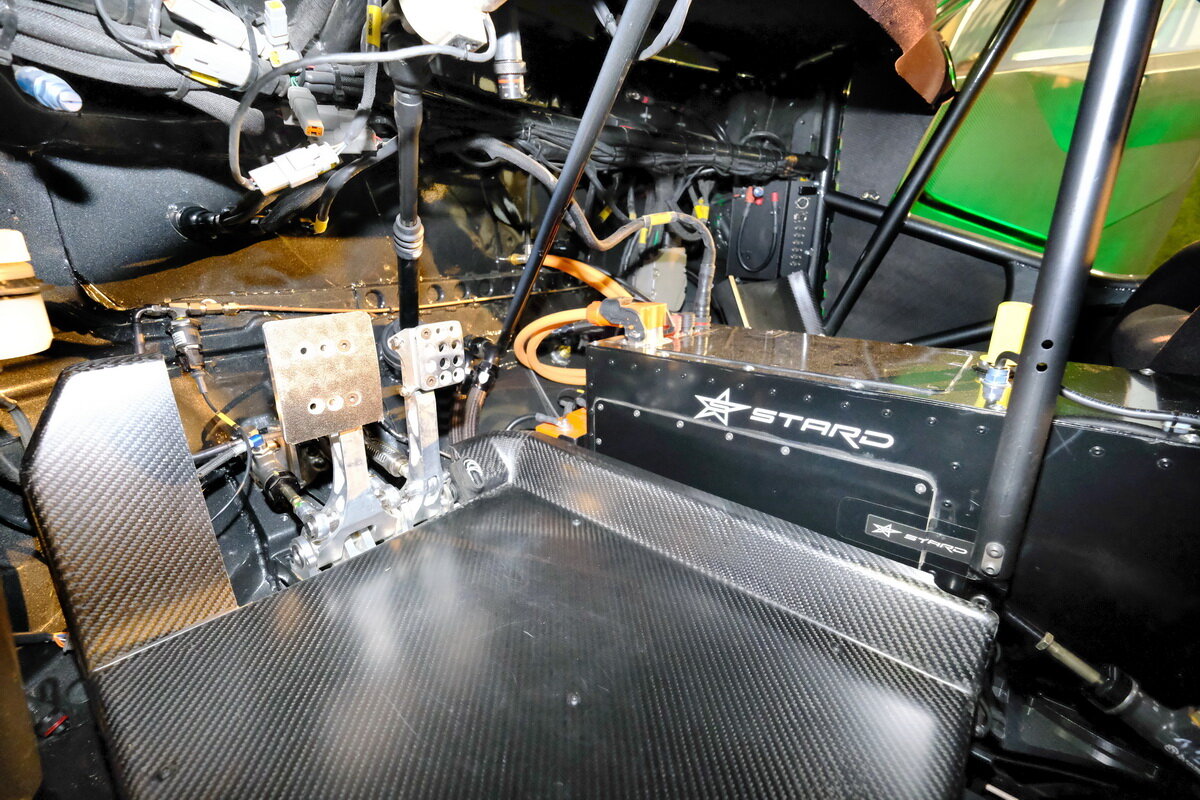

The battery electric powertrain has been developed from technology supplied by Austrian company STARD. It features advanced safety and control systems.

``It’s very similar to a Formula-E battery. It’s not like an OEM battery and it has a fire system built into it.

``If there was a problem, we have so much control technology in the car to shut things down before anything goes wrong. In the worst-case scenario, it’s got the emergency flood connectors. You flood the battery to stop the car from going on fire.

``The safety in the car is quite is quite phenomenal. It’s not like taking an OEM EV car, putting a roll cage in it and making it a club car. That’s a lot higher risk.

``That’s where it’s difficult for Motorsport NZ going forward, because it’s almost like two sets of regulations between an OEM car and a be-spoke motorsport design EV car.’’

Ahead of development work in the coming months, Paddon believes the tuning the software will outweigh the challenges of mechanical fine-tuning and durability.

``It’s all software. Mechanically the car is way simpler. There are less working parts and it’s strong and simple,’’ he said.

``Mechanically it’s pretty sound. We’ve done two filming days now with a brand-new car and had zero mechanical problems. If you had a combustion car, imagine the amount of teething problems you would have had?

``But we can have bugs in the software. We have to go through all the programming and tuning and that’s a whole different kettle of fish.’’

In order to have the range to complete a full rally, Paddon’s team has created a quick-change battery solution.

``We want to do battery changes. We are not interested in charging on an event,’’ Paddon said at today’s launch.

``We have designed the car for quick battery changes – five minutes we can change a battery.’’

He’s not saying how big the battery is but confirmed it has a smaller storage capacity than the 64kWh battery in the standard Kona electric road car.

The team is working in scale at the moment with enough battery power for short runs at full performance. From there it can calculate the size of battery needed before locking into that expensive choice.

The big rally battery will have to be over 100kWh,’’ said Paddon.

``But right now we have to calculate what we need. The big problem is the batteries are six-figures and if you get the wrong size battery now, you’ve got a battery that’s no good to you.

``With this prototype battery we can simulate very condition – hot, cold, uphill, downhill, twisty, fast - and from all that we can calculate exactly what we need.’’

Other key areas of the development programme will be tuning the torque vectoring and regenerative braking systems and an important aspect of rally safety ensuring the car makes enough noise to warn spectators of its approach.

Paddon talked of airflow systems similar to air raid sirens that would generate different levels of noise as the car moves at different speeds.

``It makes a bit of noise but it’s not at the level we want yet,’’ said Paddon.

``We are still working on a sound generator. We were hoping to have it done by now but there have been some hold ups. It’s high up on our priority list to get that right.

``It will be a different sound. It won’t sound like a combustion car but it will be relevant and be from the inputs of the driver. It’s got to sound real and sound exciting.’’